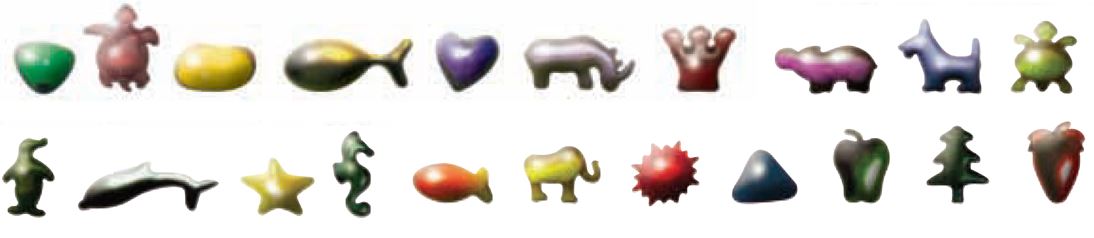

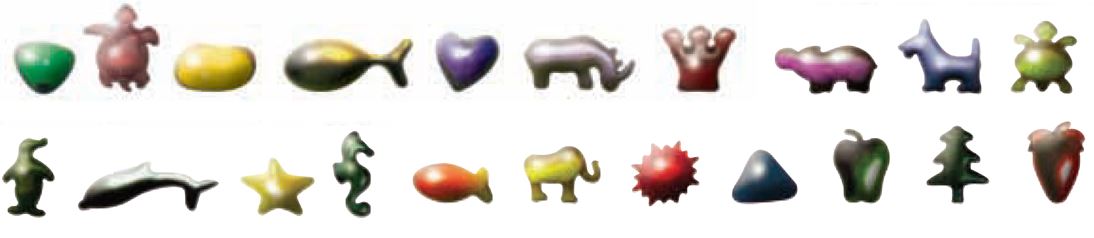

Oblong

Oblong

Oblong 3

Minims:2.3-3.0

CC:O.142-0.185

Oblong 16

Minims:14.0-16.0

CC:O.862-0.986

Oblong 6

Minims:5.0-6.0

CC:O.308-0.370

Oblong 20

Minims:16.0-20.0

CC:O.986-1.232

Oblong 9.5

Minims:7.5-9.5

CC:O.462-0.585

Oblong 22

Minims:18.0-22.0

CC:1.1O9-1.355

Oblong 11

Minims:10.5-12.2

CC:O.647-0.752

Oblong 24

Minims:20.0-24.0

CC:1.232-1.478

Oval

Oval

Oval 2

Minims:1.5-2.3

CC:O.092-0.142

Oval 10

Minims:7.5-10.0

CC:O.462-0.616

Oval 4

Minims:3.1-4.0

CC:O.191-0.246

Oval 12

Minims:8.3-12.0

CC:O.511-0.739

Oval 5

Minims:4.3-5.0

CC:O.265-0.308

Oval 16

Minims:12.4-16.0

CC:O.764-0.986

Oval 8.5

Minims:7.0-8.5

CC:O.432-0.524

Oval 20

Minims:17.0-20.0

CC:1.O47-1.232

-

Round

Round

Round 2

Minims:1.2-2.0

CC:O.074-0.124

Round 9

Minims:7.0-9.0

CC:O.431-0.554

Round 3

Minims:2.2-3.0

CC:O.136-0.185

Round 15

Minims:12.0-15.0

CC:O.740-0.925

Round 5

Minims:3.2-5.0

CC:O.197-0.308

Round 20

Minims:15.0-20.0

CC:0.925-1.230

Round 7

Minims:5.0-7.0

CC:O.308-0.431

Round 28

Minims:22.0-30.0

CC:l.355-1.848

Tube

Tube

Tube 5

Minims:2.5-5.0

CC:O.154-0.308

Tube 8

Minims:6.0-8.0

CC:O.370-0.493

Tube 17.5

Minims:15.0-17.0

CC:O.924-1.047

Tube 30

Minims:27.0-32.0

CC:l.663-1.971

Suppositories

Suppositories

Suppositories 6

Minims:5.0-6.0

CC:O.308-0.370

Suppositories 10

Minims:7.0-10.0

CC:O.430-0.620

Suppositories 40

Minims:30.0-40.0

CC:1.85O-2.246

Suppositories 80

Minims:62.0-80.0

CC:3.819-4.928

Twist off

Twist off

Twist off 5

Minims:2.5-5.0

CC:O.154-0.308

Twist off 10

Minims:7.0-10.0

CC:O.430-0.620

- Special shape

Oblong

Oblong Oval

Oval Round

Round Tube

Tube Suppositories

Suppositories Twist off

Twist off