-

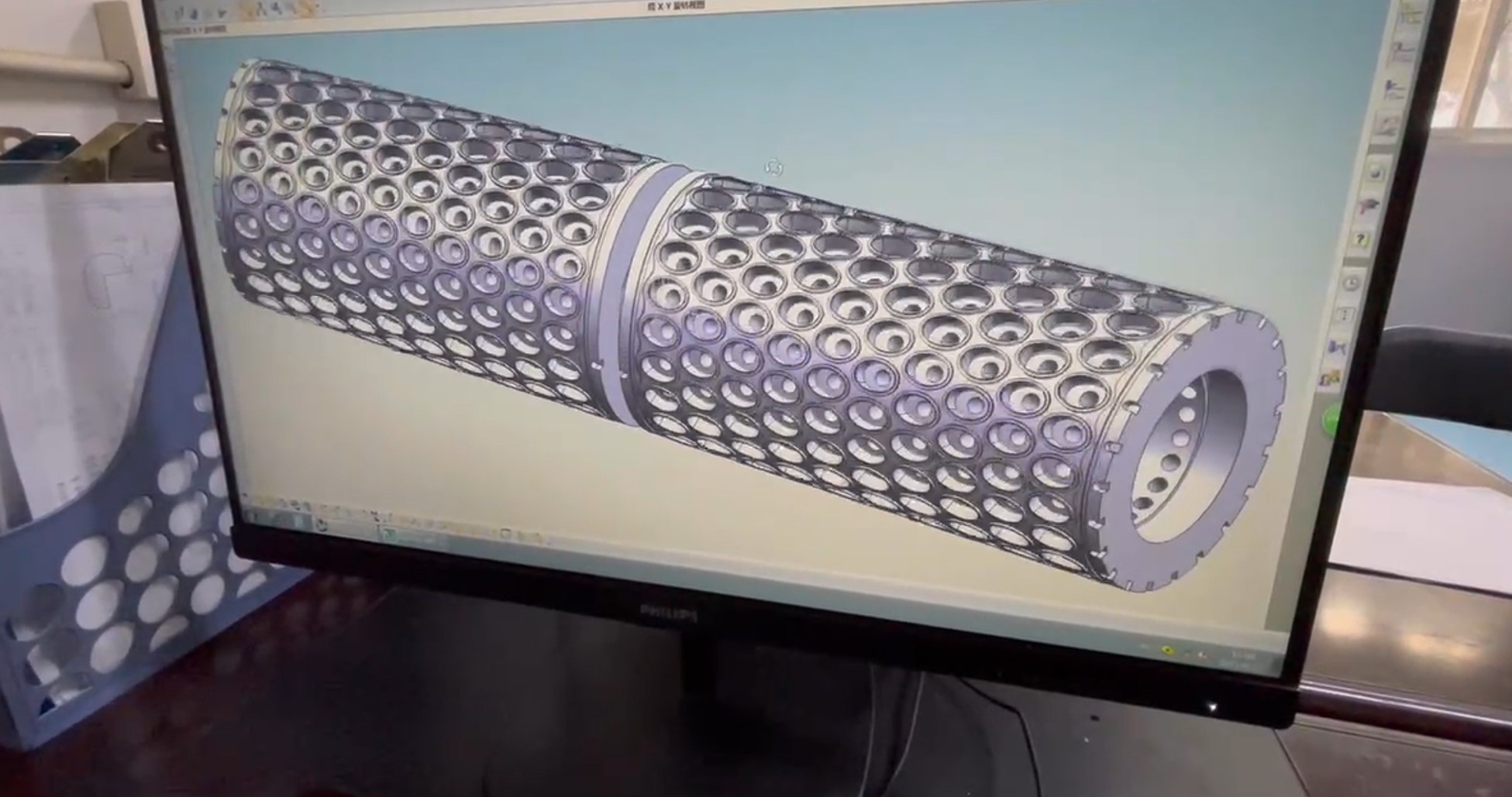

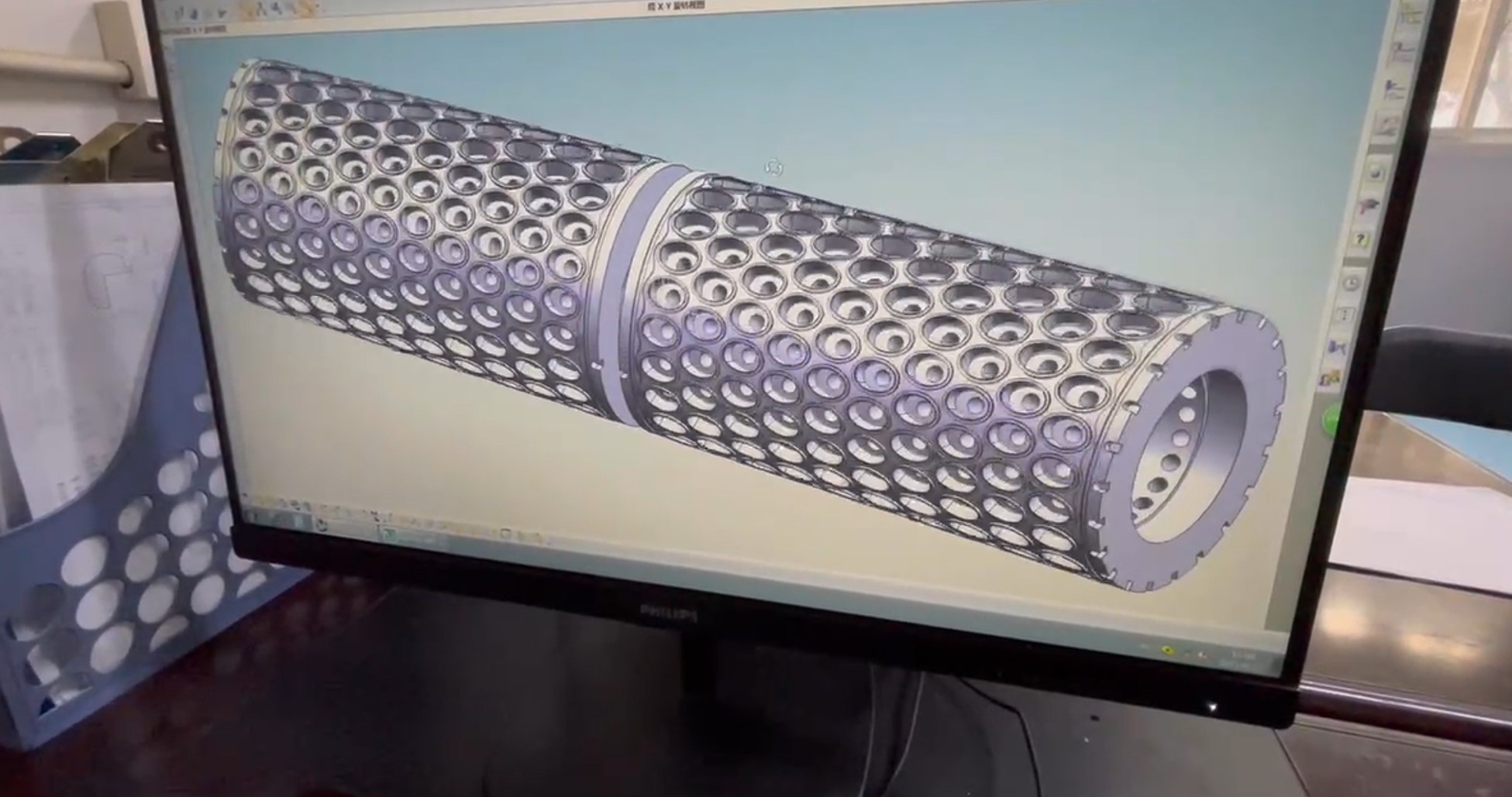

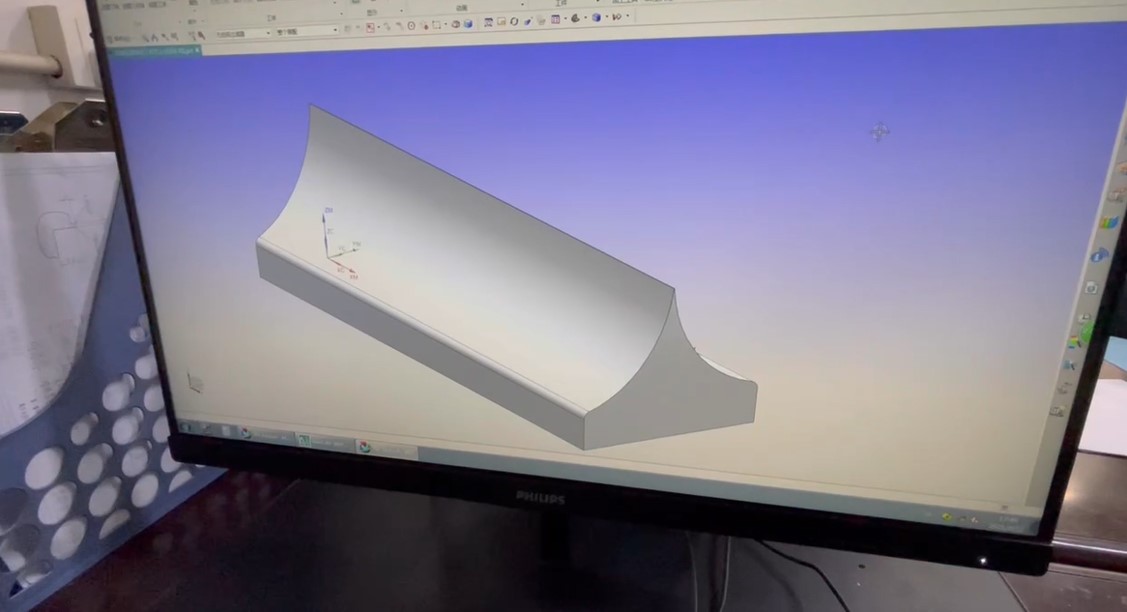

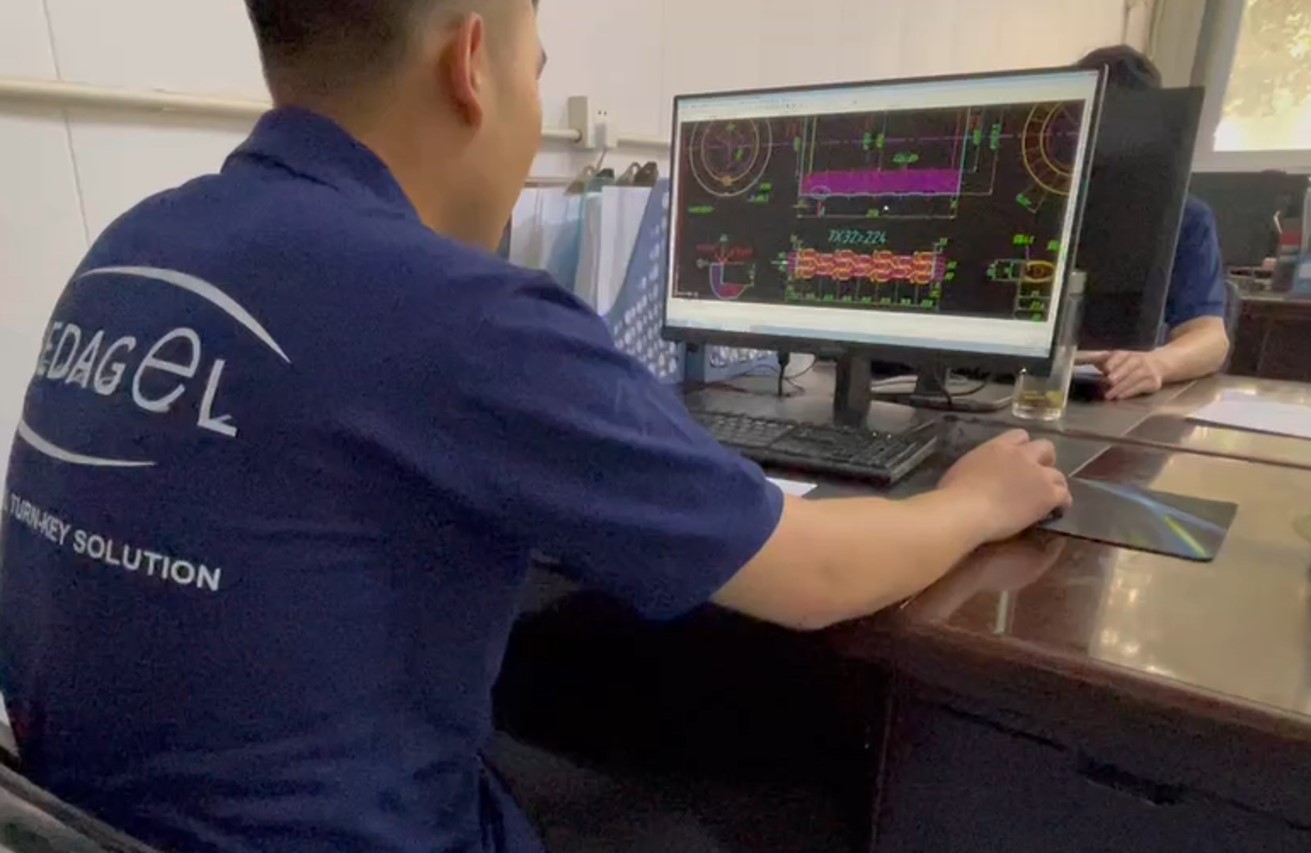

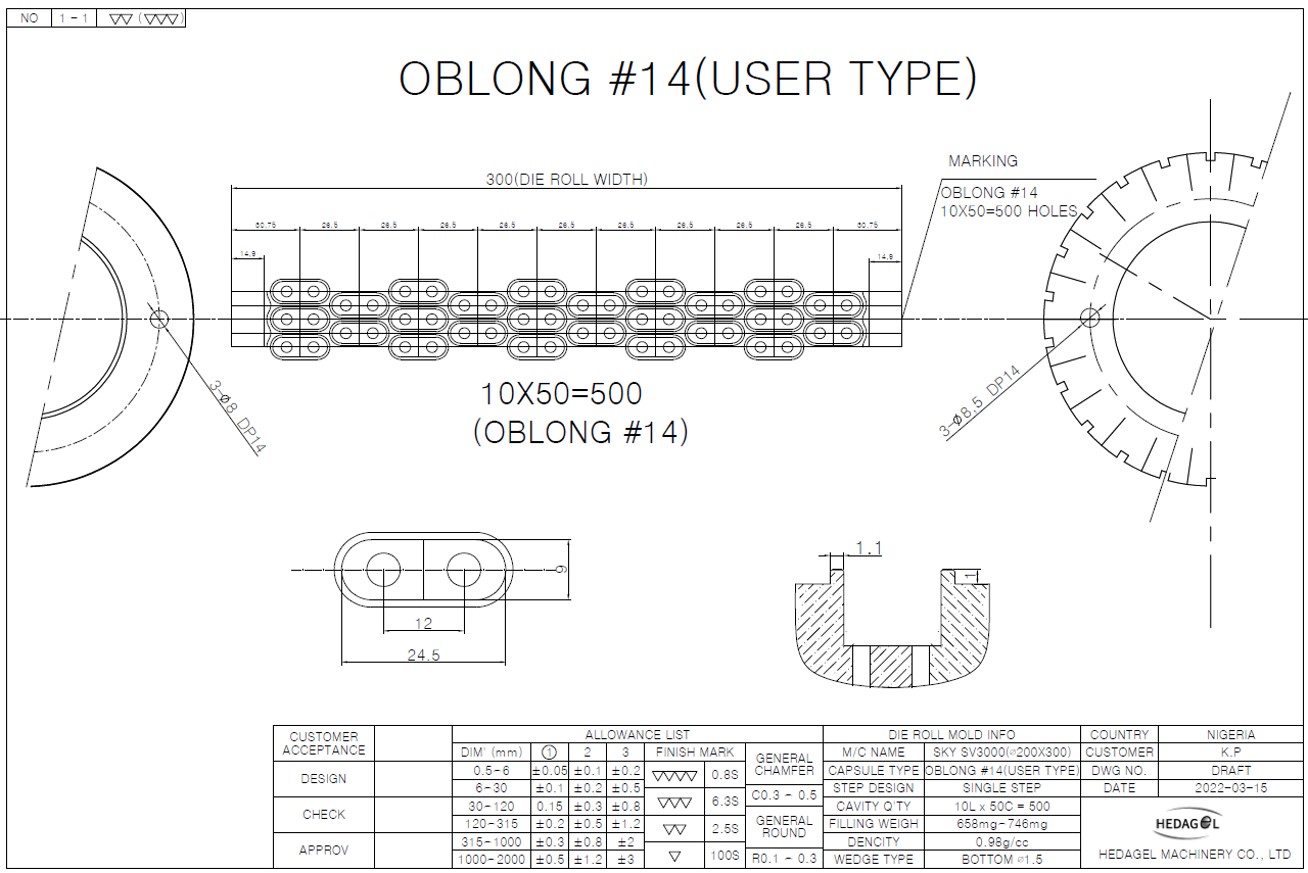

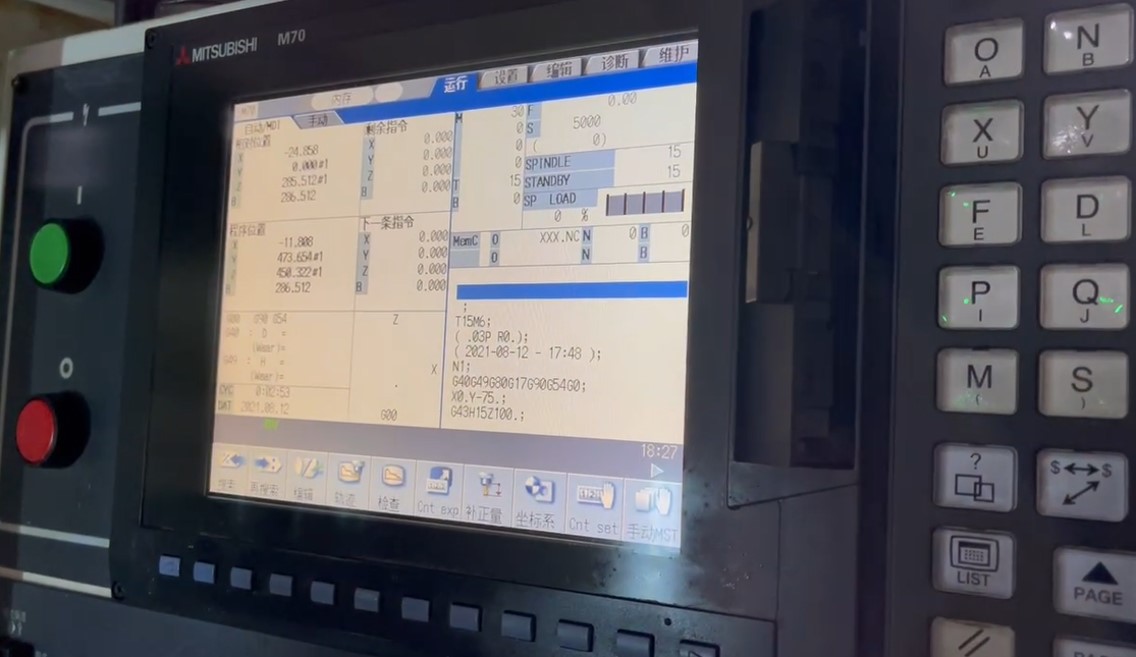

3D & 2D Design with precision

Die rolls, Wedges, Distribution plates & Timing gears design

Capsule design consultant

Special design for customer requirement

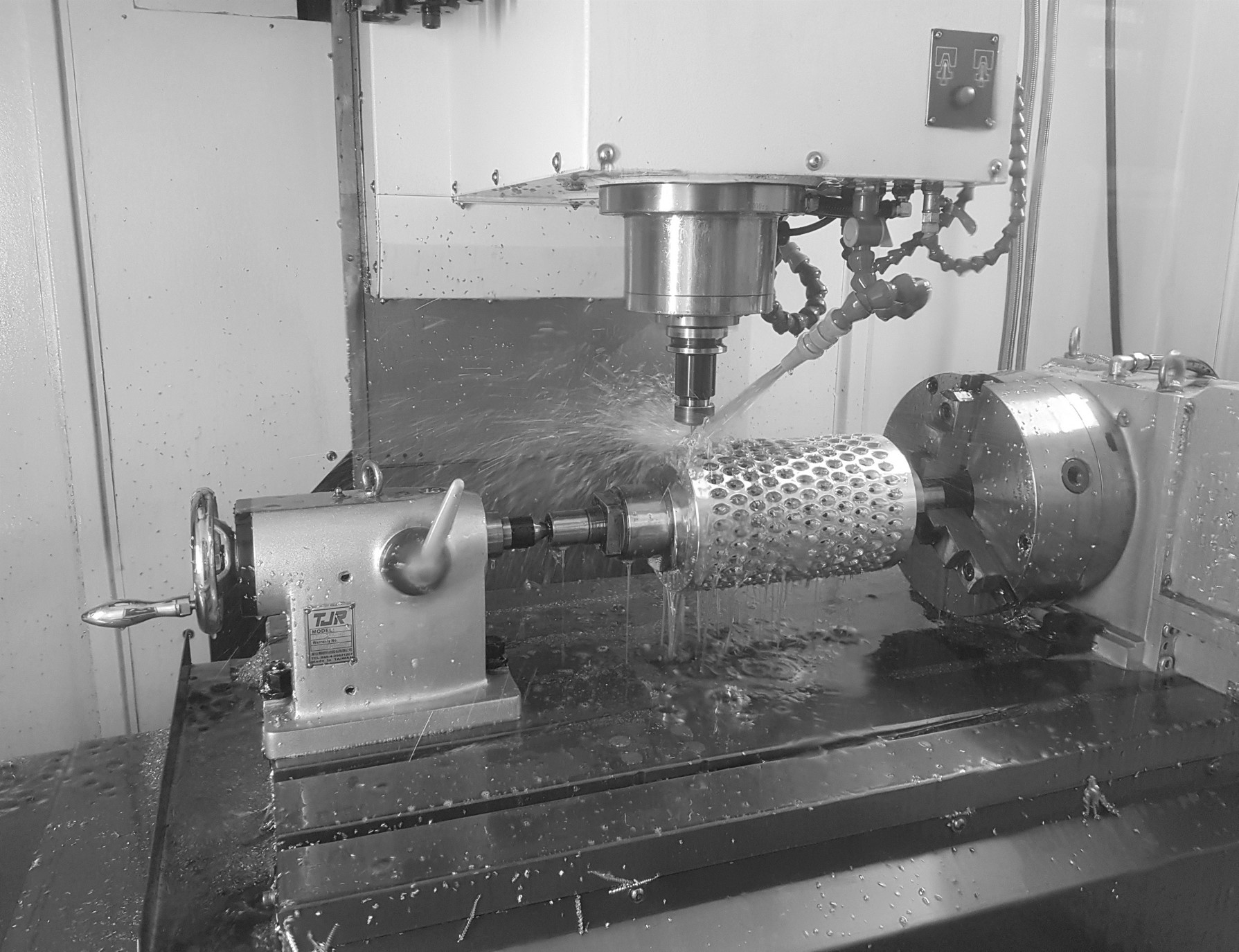

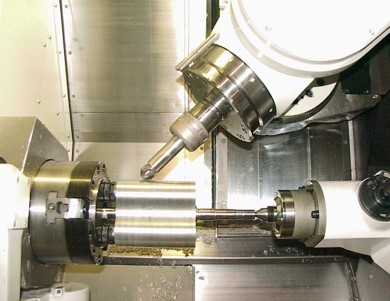

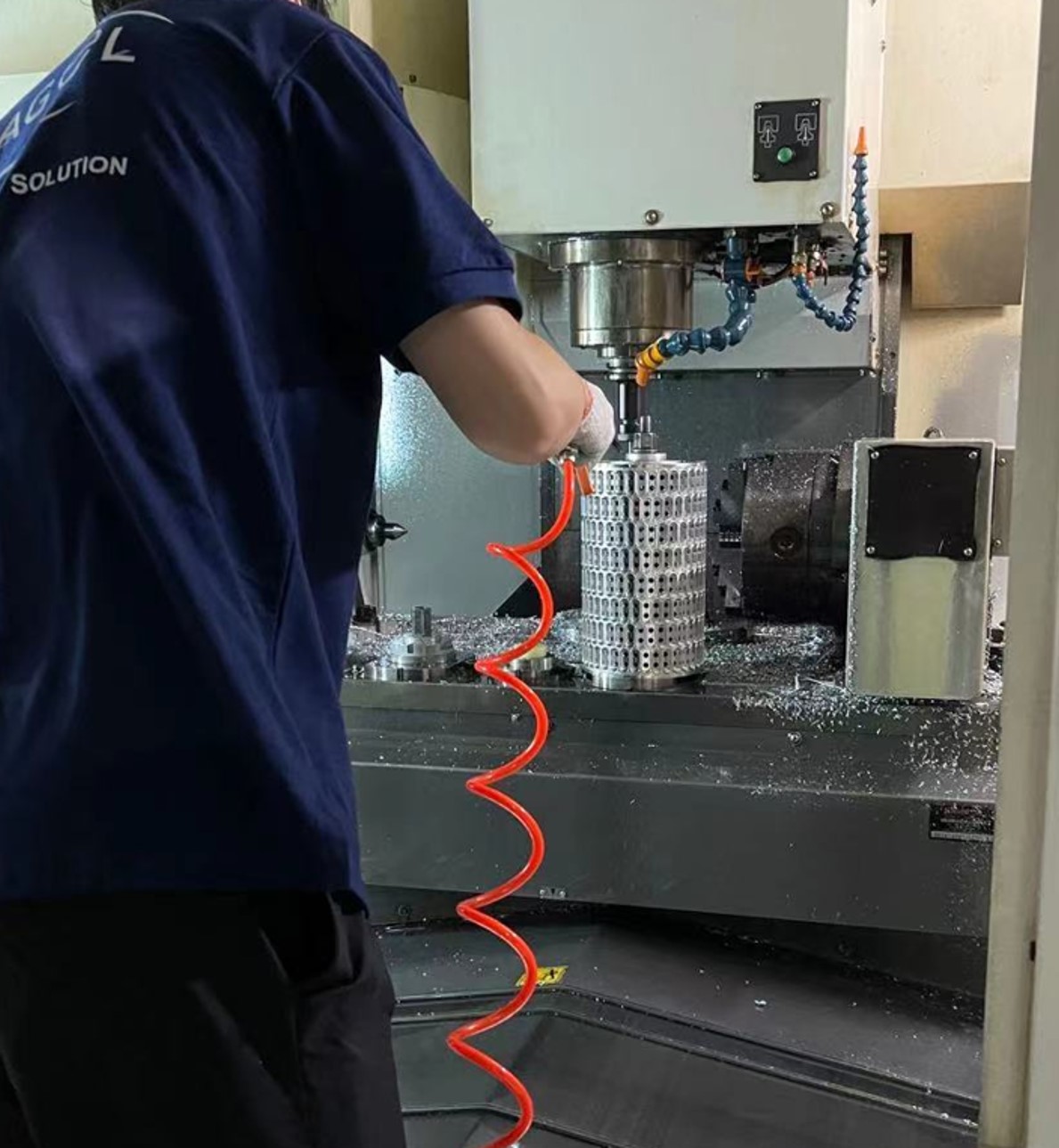

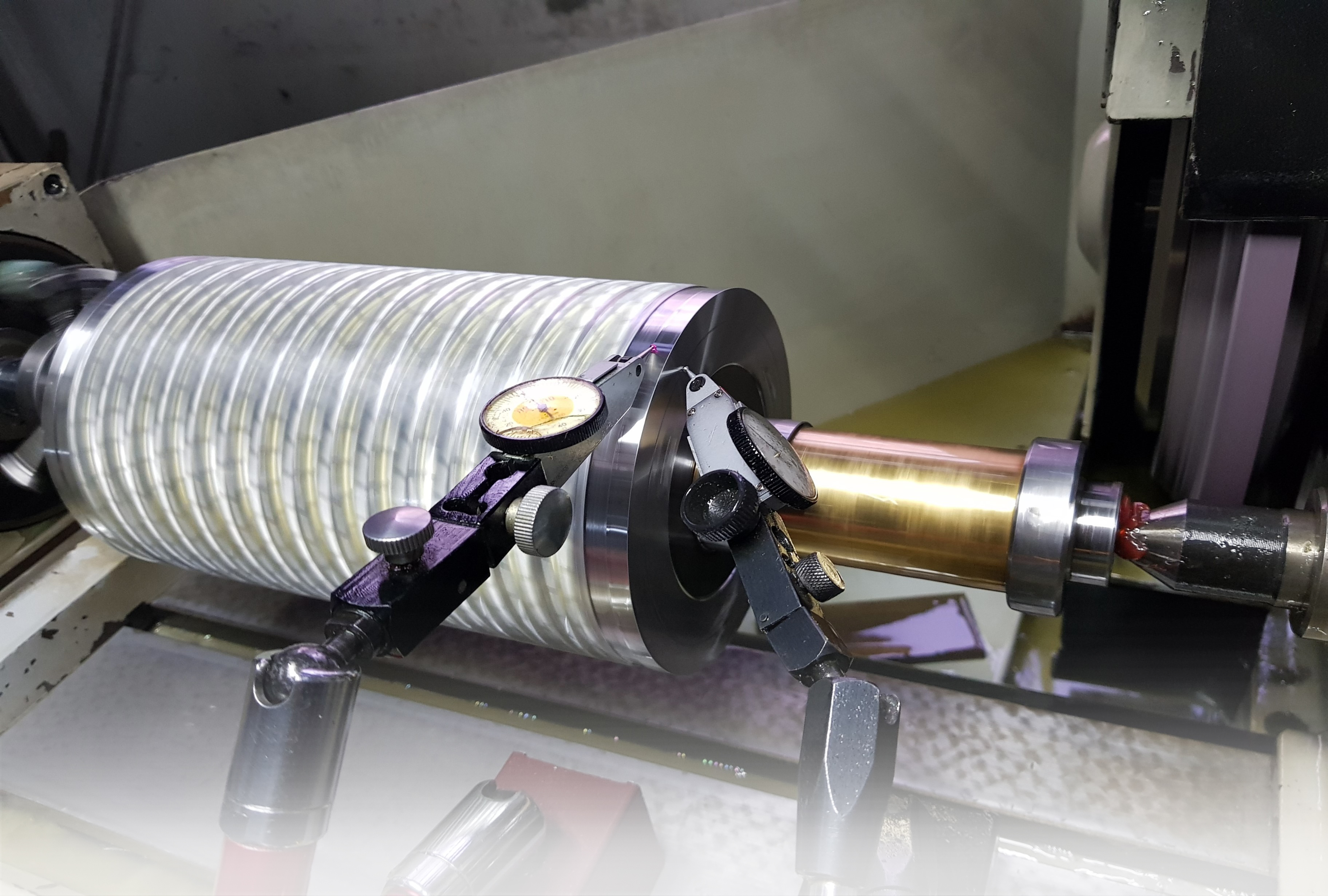

Full set die roll for customer machine

Korea, China, Canada, Japan, Italy etc.

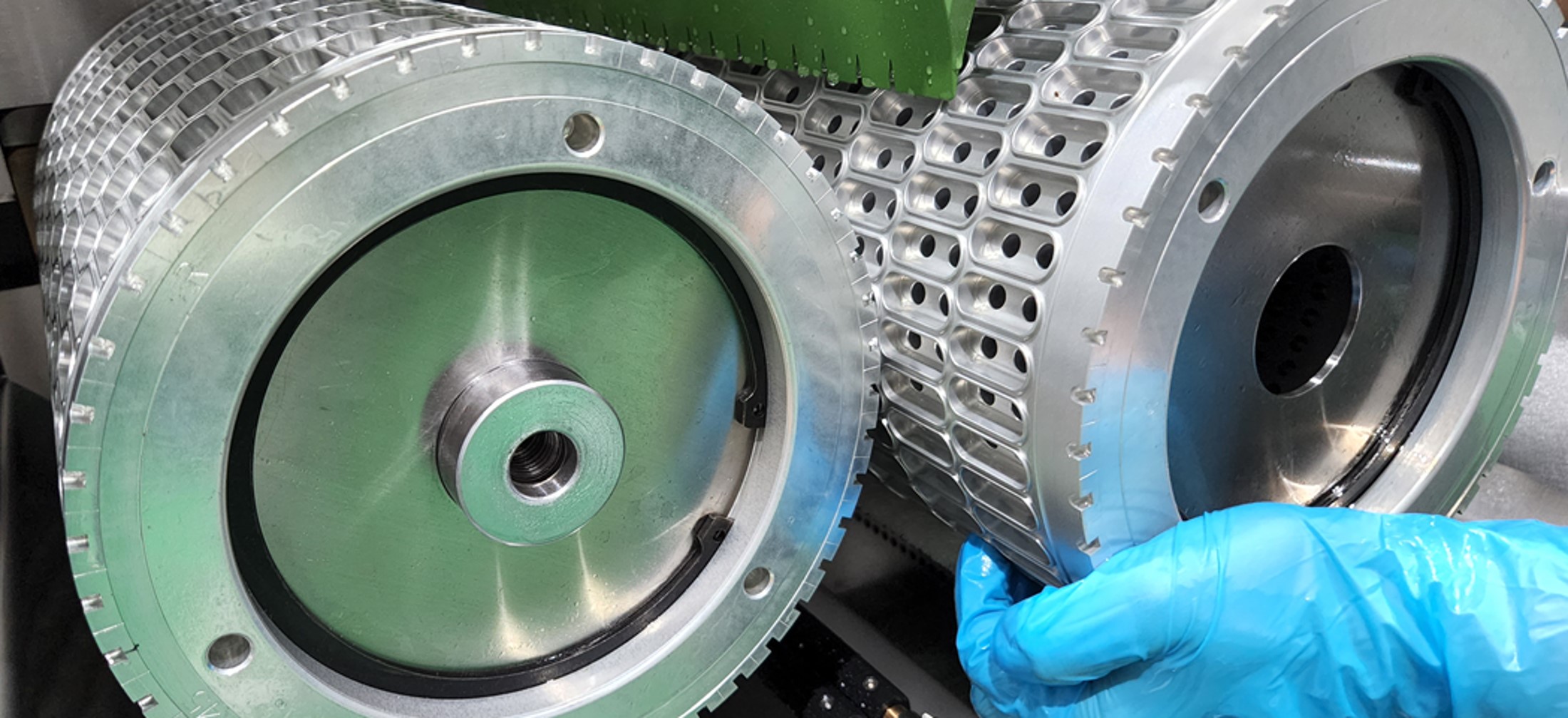

DIE ROLLS & PARTS

01

02

03

04

05